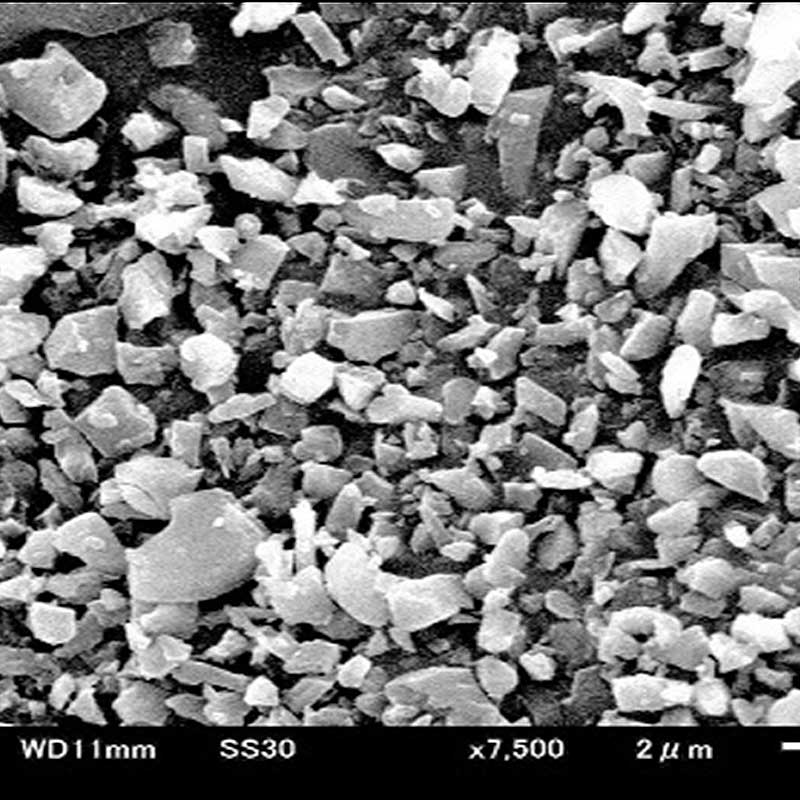

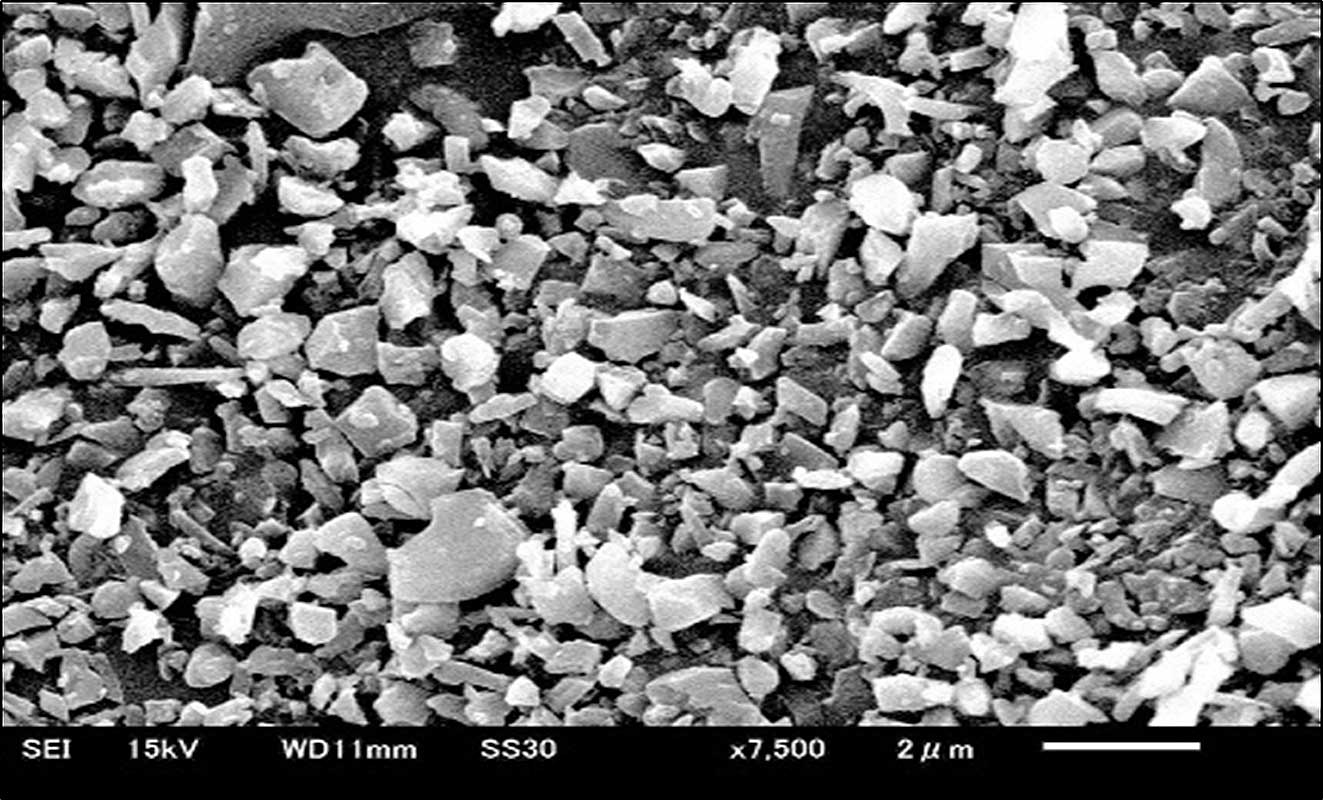

Silicon Nitride Powder SIN-P1

Silicon Nitride Powder SIN-P1

Fired & Customized Silicon Ceramic

After years of research and production experiments, Dalian ITOWU NEW MATERIAL TECHNOLOGY Co., LTD has shown that the purity of nitriding residues is high or low, deciding the pros and cons of the performance of breast porcelain products. Process and equipment, according to different standards and need to use different production methods, which can maximize the ultra-ion purity of carbon nitride ceramics.

● Silicon nitride powder span industries such as automotive, aerospace, electronics, energy, and chemical processing. Its unique combination of properties makes it a versatile material for various technological advancements and industrial applications.

● The granularity is customized silicon ceramic according to customer requirements

*SiN-P1

Customized Silicon Nitride Powder Products Supply

Silicon nitride powder is a fine, granular form of silicon nitride, a compound composed of silicon and nitrogen. Silicon nitride powder is widely used in various industries due to its unique properties and versatile applications. Customized silicon ceramics are customized in composition, shape, size, and properties to suit specific applications or desired characteristics.

Advantages of Silicon Nitride Powder

● High Strength and Hardness. Silicon nitride powder exhibits exceptional mechanical properties, such as high strength and hardness.

● Thermal Stability. Silicon nitride powder has excellent thermal stability, allowing it to withstand high temperatures without significant degradation.

● Chemical Resistance. Silicon nitride powder is highly resistant to chemical attacks, including acids, bases, and most corrosive substances.

● Electrical Insulation. Silicon nitride powder is an excellent electrical insulator.

● Thermal Conductivity. Although not as high as other ceramics, silicon nitride powder still possesses good thermal conductivity.

Applications

● Ceramic Components: Silicon nitride powder is often used to fabricate advanced ceramic components, including crucibles, substrates, seals, and insulators.

● Protective Coatings: Silicon nitride powder can create protective coatings on various substrates. These coatings provide enhanced wear resistance, thermal barrier properties, and protection against chemical attack.

| Grade Test item | SiN-P1 | SiN-P2 |

| N% | ≥38 | ≥38 |

| O% | <1.0 | <1.0 |

| C% | <0.10 | <0.10 |

| Si free% | ≤0.15 | <0.05 |

| D50 μm | 0.5~2.0 | ≤1.0 |

| Fe(ppm) | <1800 | <200 |

| Al(ppm) | <600 | <300 |

| Ca(ppm) | <300 | <100 |

| αPhase% | ≥92 | ≥92 |

Get A Quote