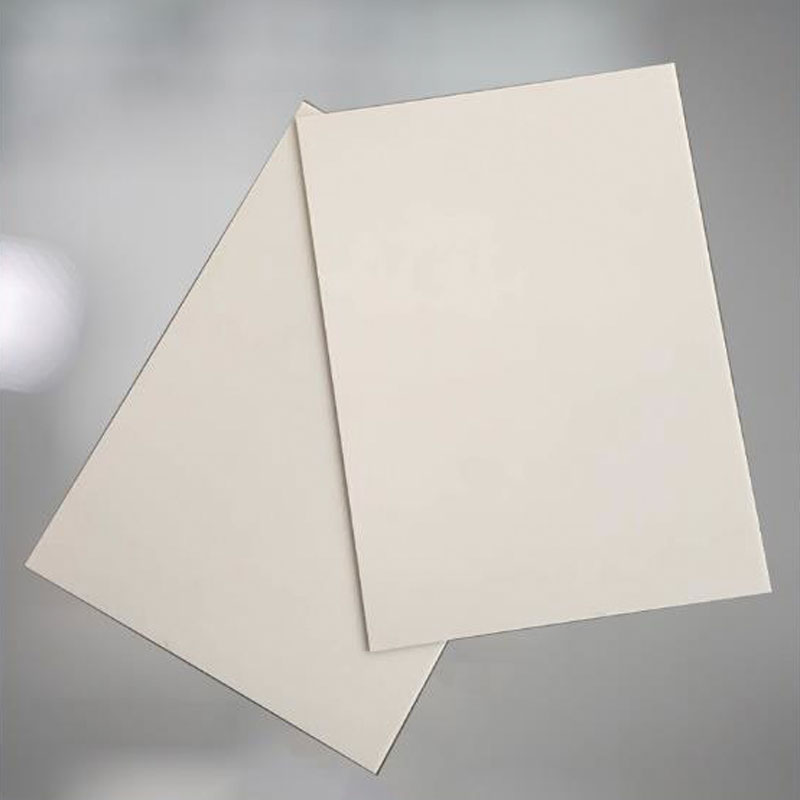

Substrate

Substrate

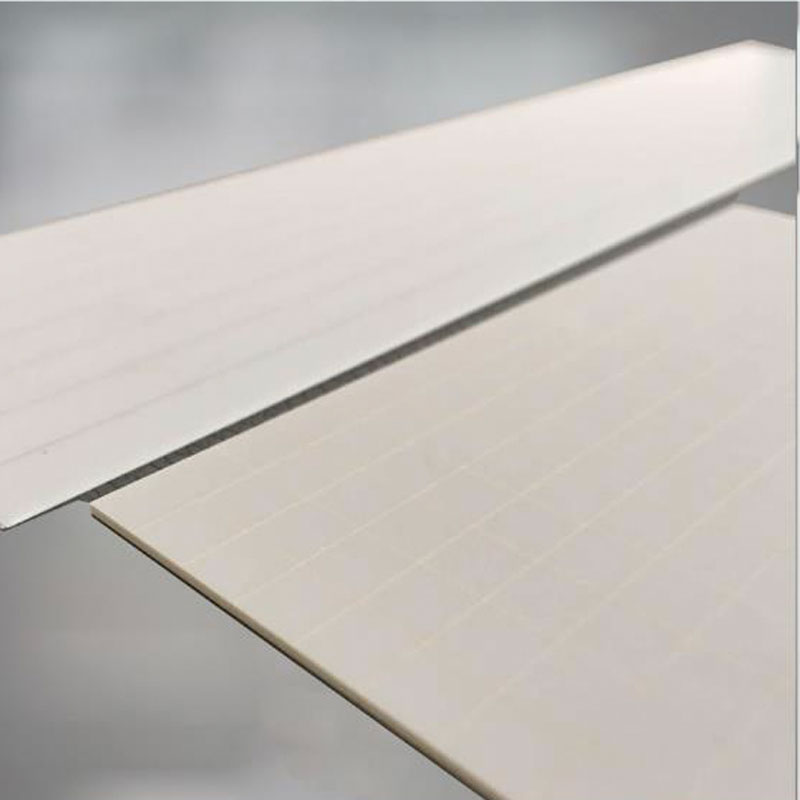

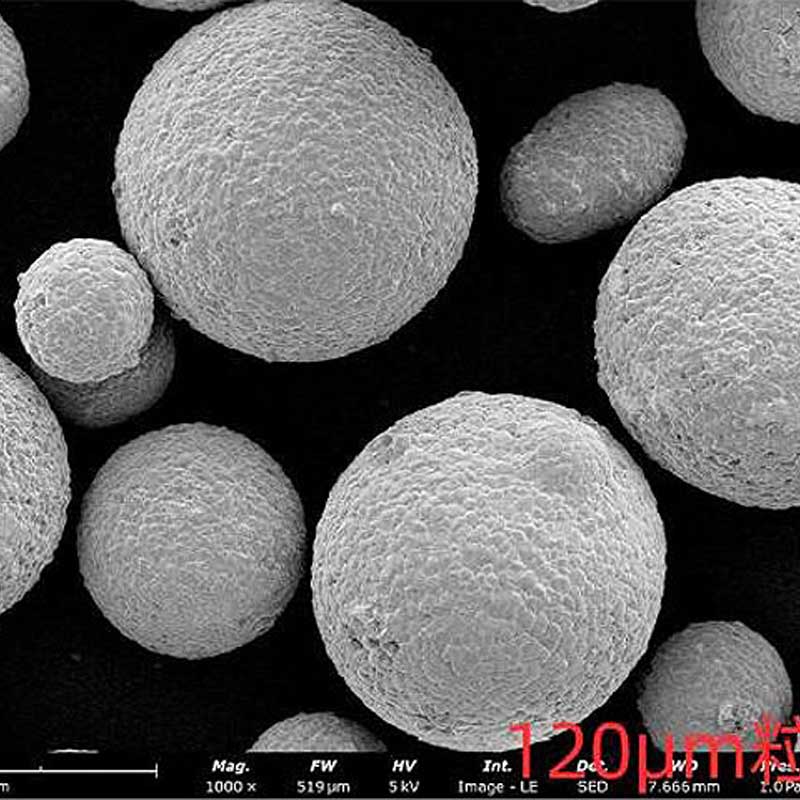

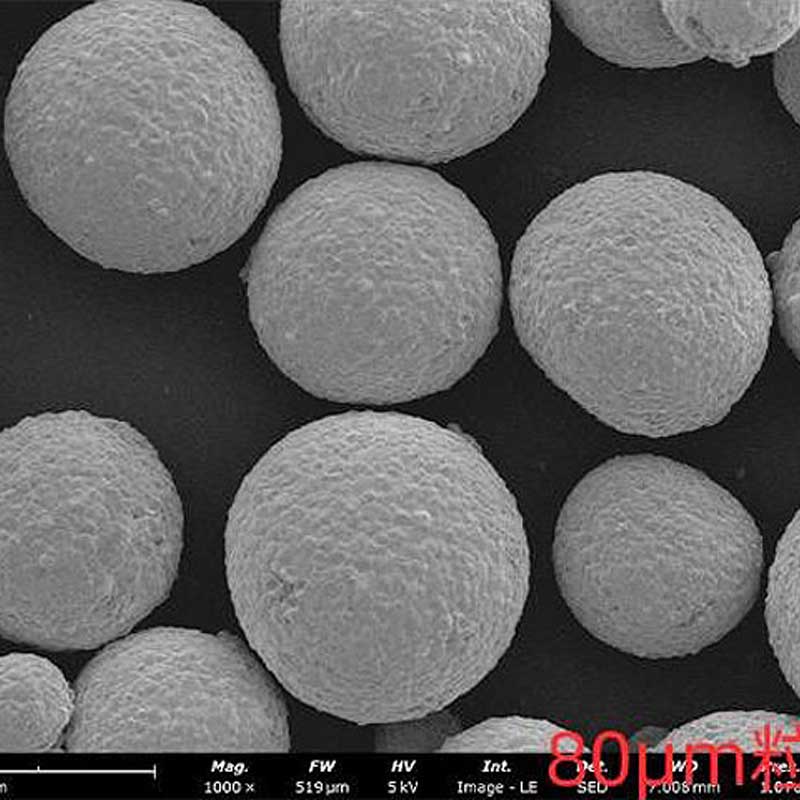

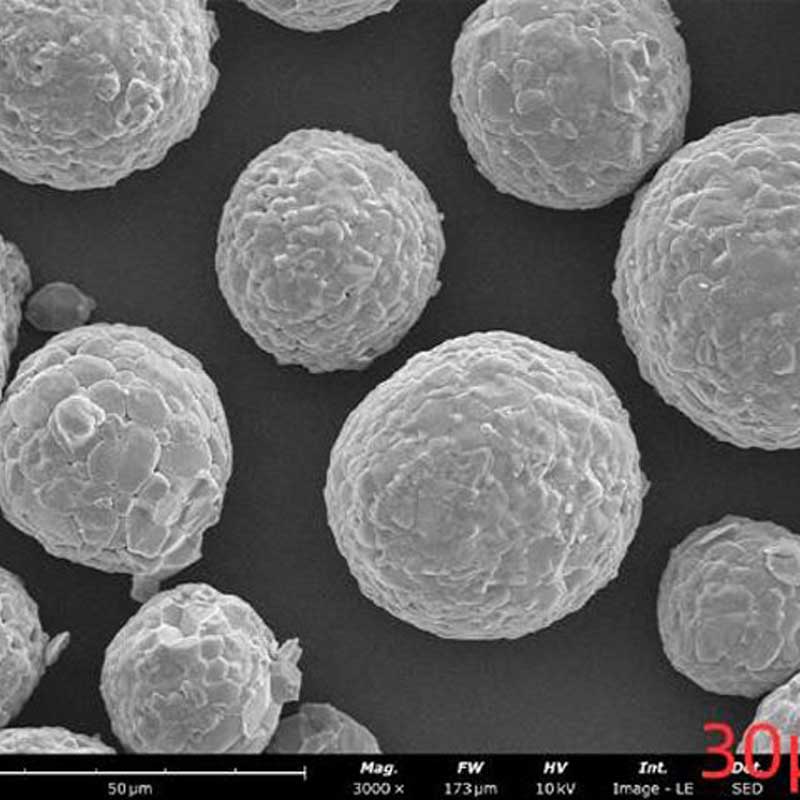

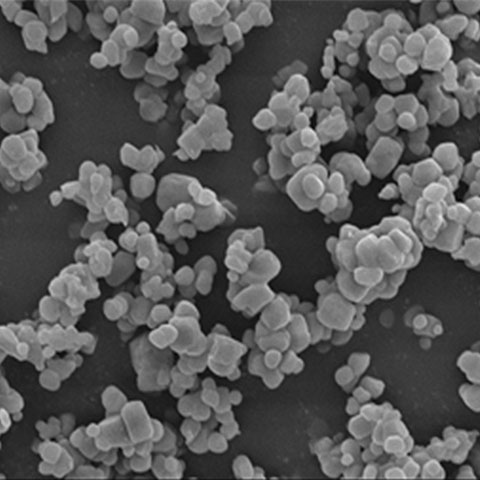

Aluminum nitride substrates were fabricated using the Tape casting . According to the different requirements of customers, aluminum nitride substrates are further subdivided to meet the metallization requirements of different applications

Product advantages

1. From the research and development of raw materials to the finished ceramic products are all independently developed and produced.

2. Standard thermal conductivity 175W/m.k, super high thermal conductivity 200W/m.k.

3. Provide customized service, can customize abrasiveness, bending resistance, high thermal conductivity, polished type, laser scribing type substrate.

4. Suitable for various metallization; DPC, DBC, TPC, AMB, thick film printing, thin film printing.

5. The thinnest thickness can be 0.01mm.

| Item | Unit | Parameter |

| Color | - | Gray/Beige |

| Thermal conductivity | [@20°C] W/m·k | ≥170 |

| Flexural Strength | MPa | > 380 |

| Surface roughness | μm | 0.02-0.07 |

| Warpage | ‰ | <2.5 |

| Bulk density | g/cm3 | ≥3.24 |

| Linear expansion Coefficient | [RT-300°C]10-6mm/°C | 4.6 |

| Volume resistance | Ω·cm | 1.5X1013 |

| Dielectric constant | [@1MHz] | 10.6 |

| Dielectric loss | [@1MHz] | 4.6X10-4 |

| Dielectric strength | (KV/mm) | ≥20 |

Get A Quote