Thermal conductivity is essential in manufacturing and can even become crucial when producing certain products. Choosing the suitable materials to create items that need to conduct heat adequately can be confusing, but boron nitride (BN) offers several advantages in this subject. We’ll go into more detail about the role of boron nitride in thermal conduction in this article.

Science of BN

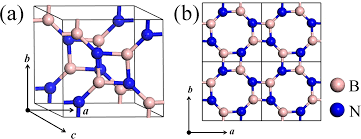

Boron nitride (BN) is a compound composed of boron and nitrogen with a molecular formula of BN. It exists in various crystalline forms, each with unique properties and characteristics.

The hexagonal form of BN is similar in structure to graphite, with each boron atom surrounded by three nitrogen atoms and vice versa. This arrangement gives rise to its high thermal conductivity, making it an excellent material for heat management applications. The cubic form of BN, on the other hand, has a diamond-like structure and is known for its high mechanical strength and chemical stability.

The properties of BN are influenced by the types of bonds between boron and nitrogen atoms. The covalent bonds between the atoms are responsible for its high thermal conductivity and excellent chemical stability. Additionally, BN's ability to conduct heat is enhanced by its unique crystal structure, which allows for the transfer of heat through the material's layers.

The characteristics of BN make it an ideal material for a wide range of applications. In addition to its high thermal conductivity, BN is also an excellent electrical insulator, making it useful in the electronics industry. Its chemical stability and resistance to oxidation make it suitable for use in high-temperature environments. Furthermore, its lubricating properties make it a popular material in the metalworking industry.

In conclusion, the molecular structure and properties of BN, the various types of BN, and their characteristics, as well as how BN achieves high thermal conductivity, are all important aspects of the science of BN. This knowledge is crucial for the development of new and innovative applications of BN in various industries.

Applications of BN

Different industries can benefit from boron nitride, making it a versatile component in the manufacturing process. Here are some examples of areas where boron nitride could be used:

- In electronics, it’s possible to use the heat conductivity that boron nitride offers to manufacture computer parts like GPUs and CPUs. Power transistors can also utilize this particular feature that boron nitride offers. In addition to these areas, BN is sometimes used as a substrate when installing heat sinks in computers and servers.

- In metalworking, boron nitride becomes a beneficial lubricant. It’s also used as a release agent when forging and casting. BN can be used as a mold material when casting at extremely high temperatures.

- The density and overall quality of ceramics can also be effectively improved when manufacturers create a mixture of materials containing boron nitride.

- Boron nitride has potential as a thermal insulation material in the aerospace industry. In this scenario, the manufacturer may utilize boron nitride in engine components that get hot at the rocket’s nozzles.

- In cars and trucks, the chemical is sometimes used in certain components that reach high temperatures. These components include the exhaust system, brakes, and the engine.

These are only some potential applications of boron nitride, providing solid evidence of its usefulness in the modern day.

ITOWU’s BN Products

Regarding boron nitride products, ITOWU has been recognized as a top-rated supplier. ITOWU offers boron nitride in powder form with a high purity level. Processed alongside ceramic, some of the boron nitride products make incorporating this material into projects significantly more accessible.

ITOWU also understands many cases where a simple or generic solution will not fit every project. This is why ITOWU offers a diverse selection of customization options that can be used to ensure the boron nitride provided to the customer is perfectly suitable for their particular requirements.

ITOWU works closely with every client to determine their exact needs. This is one part of what makes the customization system such a powerful option for us. Our expert staff can recommend the most suitable path forward by explaining the application you want to use boron nitride.

Conclusion

Finding the right partners for your chemical requirements can be an arduous task. Quality, customer service, and several other factors need to be considered. With ITOWU as your partner, you’ll never have to search again. ITOWU offers a diverse selection of nitride products that helps you manufacture top-quality products, regardless of your industry. Reach out to ITOWU to discuss the options we have and learn more about our process.