Silicon Nitride Ceramic is a versatile material with a wide range of applications. Because of its many benefits, it has established its significance across various industries. As one sort of Silicon Nitride Ceramic, the Silicon Nitride Ceramic Ball has many characteristics that allow it to excel in various demanding environments, especially in New Energy Vehicle (NEV) manufacturing. But do you know why? Read on to learn the top 3 reasons to apply it in NEV manufacturing.

Silicon Nitride Ceramic Ball – Overview

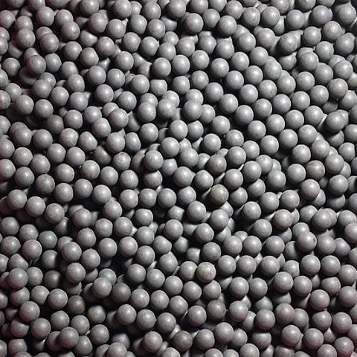

Silicon Nitride Ceramic Ball is a high-performance ceramic compound that is well-known for its unique characteristics. Composed of silicon and nitrogen atoms, this ceramic material features great strength, wear resistance, and thermal stability. The synthesis involves sintering silicon nitride powder at high temperatures which results in a dense and structurally robust material.

The effectiveness of Silicon Nitride Ceramic Ball originates from its unique crystal structure which gives it impressive thermal and mechanical properties. Its covalent bonding provides inherent strength and hence, allows it to withstand extreme mechanical stresses and resist wear even in demanding environments. The thermal stability of this ceramic ensures consistent performance across a wide temperature range. Because of these traits, Silicon Nitride Ceramic plays a key role in enhancing performance, durability, and efficiency in many industries, including New Energy Vehicle (NEV) manufacturing.

Top 3 Reasons to Apply Silicon Nitride Ceramic Ball in NEV Manufacturing

Silicon Nitride Ceramic Ball boasts several key attributes that align perfectly with the prerequisites of NEV manufacturing. The following are the top 3 reasons that highlight its significance in this field:

- Low Density and High Wear Resistance Material

NEVs thrive on efficiency and using low-density materials is important to achieve optimal energy consumption. Thanks to its remarkably low density, Silicon Nitride Ceramic Ball contributes to reducing the overall weight of the vehicle components. Furthermore, its exceptional wear resistance ensures prolonged durability and reduces the need for frequent replacements and maintenance.

- Better Insulation

Electrical components within NEVs require robust insulation to ensure seamless operation. Silicon Nitride Ceramic Ball has excellent electrical insulation properties. Because of this, it protects sensitive electronics from potential disruptions and enhances the overall safety and reliability of the vehicle.

- Smoother Surface

The surface quality of components deeply impacts their efficiency and performance. The smoother surface of the Silicon Nitride Ceramic Ball significantly reduces friction and wear. In this way, it helps ensure an extended component lifespan.

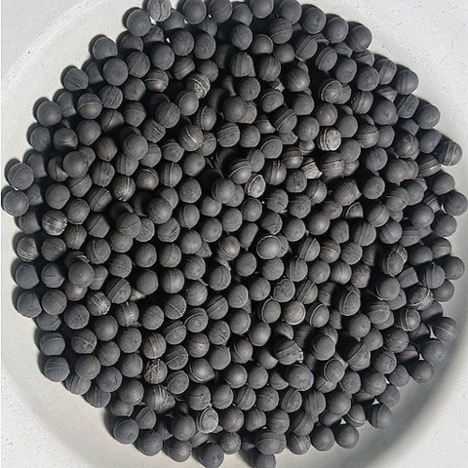

Product Recommendation: SI3N4 Media Balls

Established in 2018, Itowu is a leading provider of novel heat conductive materials. We specialize in manufacturing a wide range of products, specifically in the Boron Nitride Powder, Silicon Nitride Powder, and Aluminum Nitride Powder categories.

SI3N4 Media Balls is our popular offering. Manufactured to cover various applications, including NEV manufacturing, it has the following key characteristics:

- High temperature and corrosion resistance, which is ideal for use in complex and harsh working conditions

- Low-density Silicon Nitride product, which is 59% lighter than a steel ball to ensure reduced centrifugal force and friction in bearings.

- 40% higher modulus elasticity than steel, which minimizes elastic deformation and reduces machine tool vibration.

- Non-magnetic nature, which ensures electrical insulation without adhesion or abrasion.

- Low thermal expansion coefficient, which can withstand sudden temperature changes.

- Low friction coefficient, which has an extended service life.

Conclusion

Overall, the significance of Silicon Nitride Ceramic Balls in NEV manufacturing cannot be overstated. Its unique characteristics directly address the stringent demands of this industry and enhance efficiency, reliability, and performance. Considering its increased popularity in various sectors, many brands these days offer these high-quality products. But we, Itowu, can provide you with the premium SI3N4 Media Balls. Our industry experience, specialized knowledge in nitride ceramic applications, and commitment to delivering reliable solutions make us a trusted partner for your NEV manufacturing needs. Our high-quality products and short delivery time are well-received among customers from all around the world, and Itowu's R&D and production capabilities set it apart from the competition. Visit our official website to browse more products like the SI3N4 Media Balls and learn how we can improve your NEV manufacturing.